| Piston push type centrifuge | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

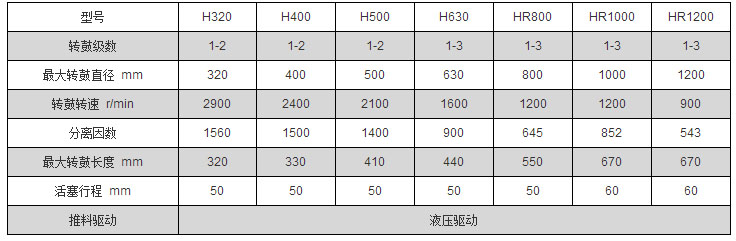

Classification: single stage piston push type centrifugal machine, double stage piston push type centrifuge The working principle: Piston pusher centrifuge main motor driven drum reached full rotation and suspension through the feeding tube continuously sent to the cloth wheel, under the action of centrifugal force, suspension evenly distributed to the drum sieve. Most of the liquid through the screen slot and the drum wall holes throw in a drum while the solid is trapped in a sieve, forming an annular filter cake. In compound hydraulic cylinder, the piston pushes drum makes horizontal reciprocating movement, when the drum level return motion, relative to the cake along the axis of the drum moves at a distance, and when the process of horizontal movement of the drum, vacated the screen surface and are continuously added suspension full, forming new cake. Such a reciprocating movement of the filter cake to push forward, and further dehydration. The cake is pushed through one or multistage drum enter trough, installed in the last stage of drum blade cake from the cut to the discharge port unloading machine. The filtrate and the washing liquid are discharged through the liquid discharging port. The main features: 1, fully automatic continuous operation, high efficiency and stability of the horizontal hydraulic unloading centrifuge. 2, suitable for solid particle size in the 0.05~5mm (more than 250 mesh), the solid-liquid volume ratio can be adjusted to 40%, feed stable production process 3, continuous operation, stable operation, separation factor is high, large production capacity, high yield, good washing effect, filter cake moisture rate is low, mother liquor containing less solid content < br / > 4, suitable for the separation of solid particle size is greater than 0.08mm, the concentration of more than 40% of the suspension. 5, applicable in, chemical, light industry, salt industry, food and other industries, such as sodium chloride, potassium chloride, potassium nitrate, ammonium nitrate, sodium sulfate, potassium sulfate, ammonium sulfate, copper sulfate, phosphate, potassium carbonate, carbonate ammonium hydrogen, polyethylene, polypropylene, PVC, nitrocellulose, boric acid, sodium bichromate, urea. The technical parameters:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||